Cot grinding machines are an essential tool in the textile industry. These machines are designed to grind the rubber cots that are used in spinning machines to give them a precise, uniform shape. The process of grinding is essential to ensure that the cots maintain a consistent diameter and surface finish, which is critical for the quality of the yarn produced. In this blog, we will discuss the various aspects of cot grinding machines, their functions, benefits, and maintenance.

Function of Cot Grinding Machines

Cot grinding machines are designed to grind the rubber cots that are used in spinning machines. Rubber cots are used to grip the spinning yarn as it is wound onto the bobbin. These cots are made of high-quality rubber and are subject to wear and tear over time. To maintain the quality of the yarn produced, it is essential to grind the cots regularly to ensure that they maintain a consistent diameter and surface finish. Cot grinding machines are designed to perform this task with precision and accuracy.

Benefits of Cot Grinding Machines

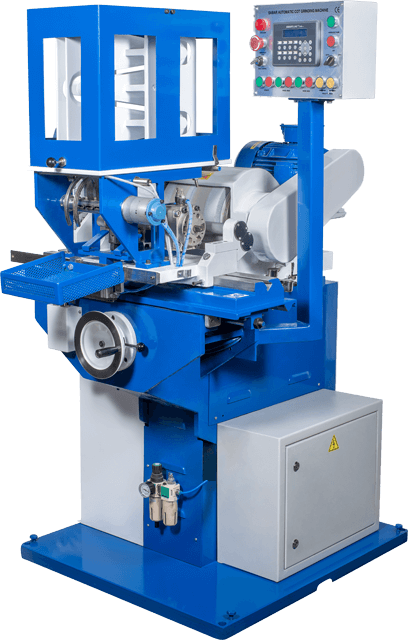

SABAR Automatic Cot Grinding Machine offer several benefits to the textile industry. The most significant benefit is the improvement in the quality of the yarn produced. By maintaining the consistent diameter and surface finish of the cots, the machines ensure that the yarn produced is of a consistent quality. This is particularly important in the production of high-quality yarn, where even small variations in diameter or surface finish can impact the final product’s quality.

Another benefit of cot grinding machines is the reduction in downtime. By grinding the cots regularly, the machines can operate for longer periods without requiring maintenance. This is important for textile mills, where downtime can be costly and impact production schedules. By maintaining the cots’ quality, the machines can operate efficiently and reduce the need for frequent maintenance.

Cot grinding machines also offer a cost-effective solution for textile mills. By reducing downtime and maintaining the quality of the yarn produced, the machines can help mills save money on maintenance and production costs. The machines are also easy to operate and require minimal training, making them an ideal investment for textile mills of all sizes.

Maintenance of Cot Grinding Machines

To ensure that cot grinding machines continue to operate efficiently and effectively, regular maintenance is required. The maintenance requirements will vary depending on the machine’s make and model, but some general guidelines can be followed to ensure optimal performance.

Firstly, the machines should be cleaned regularly to remove any dust or debris that may have accumulated. This can be done using compressed air or a vacuum cleaner. The grinding wheels should also be checked regularly for wear and tear and replaced if necessary. The machines should be lubricated according to the manufacturer’s recommendations to ensure smooth operation.

The cots themselves should also be inspected regularly for wear and tear. If the cots are damaged or worn, they should be replaced immediately to ensure that the quality of the yarn produced is not impacted. The cots should also be cleaned regularly to remove any dirt or debris that may have accumulated.

Conclusion

Cot grinding machines are an essential tool in the textile industry, providing a cost-effective solution for maintaining the quality of the yarn produced. By ensuring that the cots maintain a consistent diameter and surface finish, the machines can improve the quality of the yarn and reduce downtime. Regular maintenance is essential to ensure optimal performance and prolong the machines’ lifespan. With their many benefits, cot grinding machines are an investment that textile mills of all sizes can benefit from. For more details contact us now.