In the fast-paced world of textile manufacturing, efficiency and precision are paramount. One crucial aspect of textile production is the maintenance and grinding of cots. Cots play a vital role in spinning and weaving processes, ensuring the smooth and consistent production of high-quality yarn and fabrics. In this article, we will delve into the fascinating world of cot grinding machines and explore how they have revolutionized the textile industry.

Understanding Cot Grinding Machines

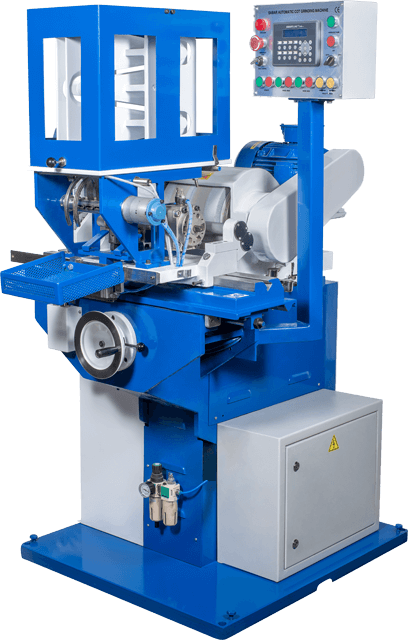

Cot grinding machines are specialized equipment designed to grind and maintain the cots used in textile machinery. These machines employ advanced technology to enhance the performance and longevity of cots, thus improving the overall efficiency of textile production. With their precise grinding mechanisms, cot grinding machines ensure that cots are perfectly shaped and have optimal surface characteristics, resulting in improved yarn quality.

Key Features and Benefits

- Precision Grinding:

Cot grinding machines utilize state-of-the-art grinding techniques to achieve exceptional precision. They can accurately reshape cots, restoring their original geometry and ensuring uniformity across the entire set of cots.

- Surface Enhancement:

By employing advanced abrasives and polishing methods, cot grinding machines can enhance the surface quality of cots. This leads to reduced friction, improved fiber control, and enhanced yarn quality, ultimately benefiting the textile manufacturing process.

- Increased Longevity:

Regular maintenance with cot grinding machines can significantly extend the lifespan of cots. Grinding removes irregularities, minimizes wear and tear, and prevents premature damage, resulting in longer-lasting cots and reduced replacement costs.

- Optimized Performance:

Well-maintained cots lead to improved performance of spinning and weaving machines. Cot grinding machines play a pivotal role in optimizing the overall production process by ensuring smooth yarn production, reducing machine downtime, and enhancing productivity.

- Quality Assurance:

Cot grinding machines enable textile manufacturers to maintain consistent yarn quality. By eliminating defects caused by worn-out or poorly shaped cots, these machines contribute to the production of flawless fabrics and garments, meeting the stringent quality standards of the industry.

Choosing the Right Cot Grinding Machine

Selecting the appropriate cot grinding machine for your textile manufacturing needs is crucial. Consider the following factors when making your decision:

- Grinding Technology:

Look for a cot grinding machine that incorporates advanced grinding technology, such as CNC (Computer Numerical Control), to ensure precise and efficient cot maintenance.

- Customization Options:

opt for a cot grinding machine that offers flexibility in grinding various types of cots, including those made from different materials and varying sizes.

- Ease of Use:

Choose a cot grinding machine that is user-friendly and intuitive, with clear controls and easy-to-follow operating procedures. This will streamline the maintenance process and minimize the learning curve for operators.

- Reliability and Support:

Consider the reputation and reliability of the manufacturer when purchasing a cot grinding machine. Ensure that they provide comprehensive technical support, spare parts availability, and prompt after-sales service.

Conclusion

The textile industry is constantly evolving, and staying ahead requires adopting innovative solutions. Cot grinding machines have emerged as indispensable tools for textile manufacturers, enabling them to optimize their production processes, improve yarn quality, and achieve remarkable efficiency gains. By investing in a high-quality cot grinding machine, textile companies can position themselves at the forefront of the industry, delivering superior products to their customers. For more details contact us now.